Rift Safety Gear Pty Ltd specialises in the production of custom-made fire-resistant/anti-static/arc rated safety apparel of the highest quality. Our garments are specifically designed for industries including oil, gas, offshore, petrochemical, electrical, emergency services and mining.

The Rift business model has achieved success by directly supplying companies that require safety apparel and PPE of the highest standard for their workforce. First established in 2007, we now supply garments and PPE to a range of national companies as well as numerous multinational organisations.

The Rift promise is to deliver technically superior safety garments and PPE that are cost competitive, whilst also providing full visibility and support to our clients throughout the order placement and delivery process.

The Rift Safety Gear promise is to deliver technically superior protective clothing and PPE equipment that is cost affective whilst providing full visibility from order placement to delivery.

At Rift Safety Gear, we understand that a paramount concern for today’s multinational companies is the health and safety of their workforce. In managing this concern effectively, the safety standards applicable to the particular field of work must be adhered to in addition to consideration of a wide range of technical, geographic and cultural factors.

As a specialist manufacturer of high end custom-made safety garments, Rift Safety Gear strives to be at the forefront of safety gear design and manufacturing. Building upon ten years of experience in this field, we work to achieve this via three broad principles:

- We offer a functional service incorporating innovative design and utilising the world’s best practices for manufacturing and fabric technology;

- By focusing on industries requiring the highest levels of garment protection, we are able to continuously develop and refine our knowledge of the demands of these workplaces;

- We strive to provide a high quality and personalised customer service experience by working collaboratively with our clients to provide solutions that promote confidence and eliminate uncertainty.

The combined effect of these principles enables us to exceed our clients’ expectations and generate a high level of customer satisfaction so that we are always the first choice when it comes to customised safety apparel.

Established in 2007, we have grown from a safety garments manufacturing company that catered for the construction, parks and gardens and civil industries to now being a high end supplier to some of the world’s most renowned global oil, gas and offshore companies.

The Rift business model has achieved success by directly supplying companies that require safety apparel and PPE of the highest standard for their workforce at the most competitive pricing.

The Rift promise is to deliver technically superior safety garments and PPE that are cost competitive, whilst also providing full visibility for our clients throughout the order placement and delivery process.

Working in partnership with Rift Safety Gear, your company will have access to:

- A superior manufacturer of technically advanced safety garments and personal protection equipment (PPE) with an established track record;

- State-of-the-art materials, selected to meet global safety standards and customer specifications;

- A collaborative design capability able to meet industry specific requirements;

- For enhanced efficiency and customer satisfaction we offer a dedicated team of Relationship Managers;

- An online e-commerce website tailored to clients’ requirements regarding access, ordering, stockholding and reporting;

- We can provide Occupational Health and Safety (OH&S) consultancy and an interactive database to meet predetermined standards and technical criteria;

- On site OH&S training to support the delivery and usage of Rift Safety Gear apparel.

Personal protective equipment (PPE) is the first line of worker protection where no other control measures are available, either as a short-term control measure or as a backup that supports more stringent OH&S control measures. Rift Safety PPE items include high visibility, technically advanced protective clothing, respiratory protection, and gloves and face masks.

From January 1, 2012, all states and territories were brought under the same legislation, the Work Health and Safety Act, Regulation and Codes of Practice. This standardisation across states and territories has helped to boost the demand for safety equipment and supplies as Australian businesses now needs to comply with these new requirements.

Australian businesses have also invested heavily in personal protection equipment to avoid workplace injuries and deaths. Whilst the number of workplace deaths in Australia has fallen over the past decade, there were still 186 workplace fatalities during 2013, according to Safe Work Australia. Desire to avoid expensive legal liabilities and negative publicity associated with workplace fatalities have also motivated businesses to invest in Persona; Protection Equipment products.

Rising awareness of the costs associated with illness and injury in the workplace is estimated to exceed $60 billion per annum by Work Safe Australia. The focus on the reduction of workplace injury has also underpinned investment in safety equipment;. Australian industry now realises the increased benefits to productivity and profitability that can come from investing in personal protection equipment to support employee health and wellbeing.

As Australian business strives to increase and accurately measure its safety record it is now moving to Total Recordable Injury Frequency Rate (TRIFR) instead of Lost Time Injury Frequency Rate (LTIFR) as a more consistent performance indicator of safety in the Australian workplace.

The total number of employees in the labour force is expected to continue growing over the next five years. With more people in the workforce, businesses need to focus on investment and maintenance of personal protection equipment to secure their work environments.

Australian business will need to comply with occupational health and safety (OH&S) requirements and ensure they have safe workplaces for their employees. Increased demand for innovative and technically superior safety equipment that is designed to meet the stringent specification of particular industry segments will be a major factor.

Rift Safety can work in partnership with your existing OH&S and corporate safety guidelines to deliver superior, personal protection equipment as an effective first line against workforce injury

Rift Safety can also provide your business with access to an OH&S Safety consultant that will keep your business totally up to date with regulatory compliance and safety standards database for all safety apparel purchases.

The Rift Safety Gear range of apparel utilises various fire-resistant/arc rated/anti-static fabrics combined with cutting-edge technology to deliver superior workplace performance. We are able to accommodate various budgets and pride ourselves in our ability to take into account a range of safety and comfort specifications.

All Rift safety garments fully comply with stringent Australian and global safety standards and are produced by various ISO-approved companies with over 20 years’ experience in manufacturing first-class safety gear for the oil, gas, petrochemical, off-shore, emergency service and mining global markets.

By matching or combining Rift safety garment characteristics to the workplace hazards relevant for your specific industry, we can ensure that your workforce will be adequately protected.

Rift Safety Gear also manufactures a full range of high-end gloves, safety glasses, footwear, hard hats, safety harnesses and accessories, life vests and hearing protection equipment, meaning that we can cater for all project procurement needs by kitting out workforces from head-to-toe.

Fire-Retardant & Inherent – AS/NZS: 2755.1985 / AS/NZS: 2801.2008 / NFPA 2112

Fire-Retardant & Inherent – AS/NZS: 2755.1985 / AS/NZS: 2801.2008 / NFPA 2112

For those industries where heat or fire present an everyday hazard, there is no room for compromise or doubt when considering the potential risks posed by sparks, excessive heat or flames. Rift have carefully created a range of flame-retardant and inherent fabrics that combine an outstanding level of protection with functionality and comfort. This includes garments made from selected fabrics that self-extinguish when the source of ignition is removed, protecting the wearer from serious burns.

The materials used in our flame-retardant and inherent garments are designed to protect on contact with flames, and convective or radiated heat. Our base-layer garments, when teamed with an outer fire-retardant layer, offer the same level of protection and due to the use of superior materials, also deliver outstanding breathability and comfort.

The NFPA 2112 Standard provides the minimum requirements for the design, construction, evaluation, and certification of flame-resistant garments for use by industrial personnel, with the intent of not contributing to the burn injury of the wearer, providing a degree of protection to the wearer, and reducing the severity of burn injuries resulting from short-duration thermal exposures or accidental exposure to flash fires.

Arc Flash Protection – NFPA 70E

Arc Flash Protection – NFPA 70E

The Hazard Risk Category (HRC) outlines the Arc Thermal Protective Value (APTV) requirement and the clothing types required to offer specific flame-resistant protection, the minimum incident energy (in calories per cubic centimetre) that protection equipment can be exposed to in order to prevent the onset of a second degree burn.

Anti-Static Protection – AS/NZS: 1020.1995

Anti-Static Protection – AS/NZS: 1020.1995

Certain natural fibres do not attract static electricity (static neutral) and therefore reduce the risk of an electric shock to the body. One hundred per cent cotton is the most common static control included in safety garments.

Many Rift inherent fabrics have anti-static fibres woven into the material, which are not seen by the naked eye. We can also manufacture various cotton or modacrylic garments, by evenly placing carbon thread one centimetre throughout the whole garment to spread the possible spark instead of creating a spark.

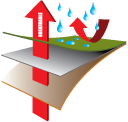

Breathable Fabrics:

Breathable Fabrics:

Hydrophilic garments pull perspiration away from your skin to the outer layer of the fabric where it is able to evaporate faster, leaving your skin fresh and without excessive perspiration.

Rift recognises the importance of providing breathable safety garments that included mesh ventilation at key perspiration points on selected garments. This type of workwear is suitable for hot, tropical climates.

Breathable, wind and waterproof clothing – AS 2001.2.18:1987

Breathable, wind and waterproof clothing – AS 2001.2.18:1987

On occasions when work must proceed whatever the weather, it is necessary to be properly protected against the elements. Any garments used should meet the AS 2001.2.18:1987 certification if comfort is to be assured regardless of precipitation and wind.

By manufacturing with Rift FRAS Oxford 300D 10000/10000wpmm material, the wearer will be kept dry for extended periods since no water will pass the through fabric membrane for up to 10 hours. This is the highest rating available for this type of fire-resistant/anti-static waterproof fabric, which has been purposely designed by Rift for our clients with projects in Papua New Guinea (PNG).

Lightweight Fabrics:

Lightweight Fabrics:

Rift have also recognised the need to develop lightweight safety garments that are appropriate for the warmest conditions.

Rift can custom-manufacture garments that are: 1/ extremely lightweight using various fabrics, 2/ use cotton rip-stop material (145gsm), 3/ appropriate for equator off-shore mining projects is our 150gsm fire inherent HRC1 modacrylic fabrics, 4/ include UV 50+ treatment with full certification to repel the suns rays.

Insect Repellent Safety Garments- DIN EN ISO 10993-1:2003-12

Insect Repellent Safety Garments- DIN EN ISO 10993-1:2003-12

At Rift we provide a range of technically advanced fire-resistant/anti-static/insect repellent garments to various companies in PNG and Africa that require more than just fire-resistant/anti-static (FRAS) protection alone.

An insect repellent treatment called Permethrin is added to the fabric manufacturing stage which provides continuous protection for at least 70 washes.

Rift’s FRAS/insect repellent lightweight garments are vital in warm tropical climates for worker comfort and safety, protecting against the risk posed by mosquitoes carrying Malaria.

High Visibility – AS/NZS: 4602.1:2011 / AS/NZS 1906.4:2010

High Visibility – AS/NZS: 4602.1:2011 / AS/NZS 1906.4:2010

High-visibility garments are a must for a wide range of industries to ensure that workers can be differentiated from their surroundings. Rift manufacture garments that are designed to be worn either during the day, at night, or both, which, for maximum protection, can include retro reflective taping at points that are suited to your work purpose.

Garments designed to meet the AS/NZS 4602.1:2011 Day Only Standard are suitable for conditions where the visibility of workers must be maximised, such as when in the presence of vehicles travelling at speed or when they must be visible at a distance, in conditions of poor visibility, or where workers may appear suddenly in the path of moving plant equipment. These garments include a minimum of 0.2m2 of high visibility fabric (AS/NZS 1906.4:2010) on both the front and back.

Garments designed to fulfil the AS/NZS 4602.1:2011 for either Day/Night or Night Standard must include retro reflective taping configured in an ‘H’ Pattern or ‘Hoop’ Pattern. High visibility material must encircle the upper body.

Rift’s garments use high visibility materials tested to Australian Standard AS/NZS 1906.4:2010, which outlines the requirements for fluorescent capabilities and the chromaticity reading to ensure that the bright hues used are within the required colour range.

UV Treatment Certification – AS/NZS:4399.1996

UV Treatment Certification – AS/NZS:4399.1996

Rift’s sun protective safety garments are specifically designed to provide protection from the sun utilising several different methods. Firstly, we use several fabrics rated for their level of ultraviolet (UV) protection, with sun protective properties derived through use of a unique weave structure and denier (referring to the thread count per inch). These fabrics include either full percentages or blends of heavyweight natural fibres (e.g., cotton, linen or hemp), lightweight synthetics (e.g., polyester, nylon, spandex and polypropylene), or natural or synthetic indigo-dyed denim, twill and canvas. We can also incorporate a further level of UV protection by pre-treating garments made from selected fabrics with UV-inhibiting ingredients.

Our sun protective clothing adheres to particular design parameters that either maximise skin coverage or provide full coverage to areas of the skin most susceptible to UV damage. We manufacture garments that are long-sleeved, include full-length trousers, skirts and dresses.

Safety Gloves – EN 388

Safety Gloves – EN 388

Rift manufactures a range of safety gloves providing protection for various different work environments. It is important to know the level of protection required with respect to the mechanical risks relevant your specific workplace environment. Gloves are tested for four different properties: 1/ Abrasion resistance, 2/ Blade cut resistance, 3/ Tear resistance and 4/ Puncture resistance, and the results are reported as performance ratings where the higher the rating, the better the glove has performed under testing. The maximum performance achievable is level 4, with the exception of ‘Cut’ which reaches a Maximum tested level of 5.

Rift manufactures a full range of Cut 1,2,3, 4 and 5 gloves, anti-vibration, mechanic and fire resistant off-shore safety gloves. We also offer gloves with a range of specific key features appropriate for different environments including puncture resistance, improved grip, heat/cold protection, flexibility and dexterity, chemical permeability and high/low voltage.

For workplaces requiring extremely high levels of hand protection, Rift’s Cut 5 level safety gloves offer a high strength-to-weight ratio of about five times that of steel with the same weight. Kevlar is also used to reduce the risks associated with cutting, snagging and tearing of fabrics and can be introduced in a custom design where the risks of cuts and nicks can be common, for example in the glass manufacturing industry.

Safety Boots – AS/NZS: 2210.3.2009 / ISO 20345:2003

Safety Boots – AS/NZS: 2210.3.2009 / ISO 20345:2003

Rift offers a variety of safety boots and shoes. All footwear is manufactured to a high quality standard and is compliant to the stringent Australian Safety Standards. Our unique designs are perfect for a range of different industries including the gas, oil, mining, emergency services and construction industries.

At Rift we use a wide variety of materials to manufacture our safety footwear including water resistant 100% nubuck leather, shock absorbing polyurethane midsoles, bevelled heel for excellent slip resistance, lace locking fixtures, padding comfort collars and a wide range of electrical resistant and anti-static PU / TPU and rubber soles.

Safety Glasses – AS/NZS: 1337.1: 2010

Safety Glasses – AS/NZS: 1337.1: 2010

Our range of eye protection is diverse and comprises numerous models and styles. We can assist companies in addressing a range of concerns such as eye fatigue, anterior and side visibility, ventilation, protection from infectious fluids and chemicals, and glare.

Our variety of styles include glasses, goggles, visors, lightweight, sealed, nickel-free, and polarised, to name but a few. We pride ourselves on our knowledge regarding the appropriate choices for different environments, meaning that you will always find the right safety eyewear at Rift Safety Gear.

Safety Harnesses – ANSI/ASSE Z359.1-2007 / CE / CSA Standard Z259.12.11

Safety Harnesses – ANSI/ASSE Z359.1-2007 / CE / CSA Standard Z259.12.11

To provide a safe environment when working at heights, we offer a wide range of equipment to protect against falls. Our harnesses are designed with efficiency, comfort and safety in mind and are ideal for industries including construction, offshore mining, emergency and sky scraper city works.

Our harness kits incorporate features including rear fall arrest, front fall arrest, padded waist bands, rear fall arrest extension straps, adjustable legs and shoulder straps, hi-visibility webbing and trauma relief straps.

We can also supply a range of height safety equipment products including anchor straps, rope adjusters, body harnesses, wrist lanyards, and body harnesses.

Life Vests & Offshore Emergency Equipment.

The Rift Offshore Twin Chamber is a life jacket designed for use in the open sea and in all weather conditions. We have ensured that the jacket is optimised for performance by being as least restrictive as possible.

The dual chamber design of this life jacket provides enhanced safety whereby should one of the chambers be damaged, the other chamber is sufficient to support the wearer while in water entirely on its own.

Rift also has other offshore emergency equipment options available to suit your company’s safety standards or specifications.

Rift Safety Gear Head & Ear Protection AS/NZS:1801.1997 / AS/NZS:1270.2002

Rift Safety Gear Head & Ear Protection AS/NZS:1801.1997 / AS/NZS:1270.2002

Rift is also a distributor of the 3M Peltor MT series two-way communication headsets which are specifically designed for industrial users in high-noise environments. Incorporating 3M Peltors technology in both ear cup design and electronics makes this headset, in conjunction with a two-way radio, the ideal choice for clear, crisp 2-way communication in high-noise areas. These 3M headset can be fixed to many of Rift’s hard hat styles that we have on offer. We also have a wide variety of other head sets and hard hat’s to suit your safety specification or company budget.

In any work environment that exposes an individual to the risk of a flash fire or explosion, products that assist in preventing a serious burn injury are a critical consideration. When mere seconds can result in a disaster, the use of flame-retardant, protective clothing might be the difference that saves a worker’s life or prevents lifelong impairment.

All workforces working in industrial environments where ignition hazards are present should wear fire-retardant clothing. Even if your company has not recorded an accident in years, the chances of someone getting seriously burned or worse are still likely present and potentially devastating. Employers who do not provide the proper fire-retardant clothing to their employees also face the possibility of fines by Work Safe Australia.

There are currently a wide range of flame-resistant fabrics on the market, at times leading to much confusion for the customer. We work closely with our customers enable them to make informed choices about those most suitable for their workplace. Rift also maintain strong relationships with fibre producers and textile mills so that we are always aware of the development and evaluation of new flame-resistant fabrics.

As such, our consultants have the knowledge and experience to assist you in answering any questions you may have about the different types of flame-resistant protective apparel, to create custom designed and manufactured garments to meet your requirements, and to ensure that you are only incorporating features that are required for your industry (thus ensuring cost effectiveness).

-

Prevent Injuries due to Accidents

The most common cause of severe and fatal workplace burn injuries are occasions when an individual’s clothing has ignited and continued to burn (as opposed to injury from the ignition source itself), since this prolongs the time that the individual is exposed to excessive and damaging heat. Even in instances where an employee is following the proper safety regulations and all steps have been taken to provide a safe workplace, accidents can still occur.Fire-retardant materials eliminate the risk of injury since they do not ignite and continue to burn, providing thermal protection at the area of exposure. The level of protection is derived from the weight and composition of the flame resistant fabric. As soon as the source of the ignition is removed, fire-retardant garments will self-extinguish which minimises the injury sustained to the body and allows the individual time to escape.Although a person caught in a flash fire or arc flash may still receive injuries, the use of appropriate fire-retardant clothing can greatly reduce their severity. In some cases, this may mean the difference between life and death.

-

Compliance with Existing Regulations

All organisations are governed by relevant Occupational Health & Safety legislation which sets out the requirements for employers in providing adequate protection from dangerous hazards in the workplace. Compliance with safety standards is necessary since it impacts the perception and reputation of your company, as well as improving employee morale and trust in their employer. There may also be significant consequences for not adhering to the legislation, for example, companies may be fined for not providing fire-retardant clothing to employees or ensuring that it is worn correctly.Since safety standards, which can include various voluntary consensus standards, are becoming ever more stringent, it is also necessary to periodically review your safety garment specifications.

-

Comfortable and Long-Lasting

We understand that fire-retardant clothing can be subject to various demands; they may be worn for long periods or in a range of climates, they may undergo frequent washing, and they may need to fit various different body shapes and sizes. We custom design our garments to suit your specific comfort requirements. This ensures that not only will they provide sufficient protection; they will also be a pleasure to wear. This is an important factor to consider because maximising comfort ensures that workers are not deterred from wearing the garments.

-

We only use the highest quality materials:

All fire-resistant/anti-static/arc flash materials used by Rift in the manufacturing of our safety garments are of the absolute highest quality and come with full test reports. They have been individually selected by our garment development specialists to provide superior protection and we are constantly seeking innovation and technological advancement in the materials that we use.We have many treated FRAS and inherent FRAS fabric options to choose from to suit your company budget and specifications.We also have varying ‘grams per square metre’ (GSM) fabric weights available that can be selected to provide the utmost comfort for the wearer.

-

Attention to detail:

Our attention to detail is unparalleled. The Rift apparel range comprises carefully chosen safety garments that deliver superior workplace performance compared to other safety gear labels available in Australia. Every fabric batch that we use meets our rigid specifications and we regularly travel to our manufacturing sites to ensure stringency in the manufacturing process for each batch of garments. We encourage trialling of our safety garments to enable companies to experience the quality of our garments and to ensure that they are completely happy with the final product.Take our Rift’s FRAS waterproof safety garments, which are light-weight and manufactured using the highest available waterproof and breathable three-layer materials available. The rating achieved for our FRAS waterproof fabric is 10000/10000wpmm, whereas most other safety labels use 5000/5000wpmm material. Thus the waterproof breathability rating represents a doubling of our competitor’s standards and specifications. We also use a heavy duty, non-breakable waxed nylon thread on all stress points of Rift FRAS waterproof garments to ensure that the garments are extremely hardwearing. The seams on all Rift waterproof garments are also taped to ensure no seam leakage.

-

Research and development:

Our research specialists have invested hundreds of hours in researching fabric technology and designing custom made garments specifically for hazardous workplaces. We are also constantly seeking to update our knowledge of new technologies to ensure that we remain at the forefront of safety garment supply and design.All safety garments designed and supplied by Rift comply with stringent Australian safety standards and are made by various trusted companies with over 20 years’ experience in manufacturing first-class safety gear for global oil, gas and petrochemical companies.

-

Customisation:

Rift Safety Gear has developed collaborative design partnerships with several global oil and gas companies to provide safety apparel that fulfils specific industry requirements.This innovative and unique approach has received praise from industry participants, allowing us to deliver technically superior solutions that have assisted companies to significantly reduce workplace injuries and meet reportable injury frequency targets. For us, custom designs are the norm rather than the exception, meaning that we can assist your company in creating garments that are ideal for your particular industry.

- We offer the highest quality garments for the best value.

- All Rift garments are supplied with test reports, ensuring confidence in the standards of protection offered.

- Our safety apparel can be designed to any specification required.

- We make quality and lead times our top priority.

- We are able to hold stock for all contracted clients. We can also create order alerts to ensure that stock levels remain at an agreed percentage.

- We provide unrivaled reliability and flexibility to maintain the highest standard of customer service.

- We understand and encourage our garments to be trialled since this allows for any final amendments prior to the bulk manufacturing stage.

- Our experienced team members work hard to assist and support our clients throughout the product development and supply process.

PAST PERFORMANCE

• Schlumberger – fire resistant / anti-static / insect repellent coveralls

• Conoco Phillips – fire resistant / anti-static / 4-in-1 jacket

• Queensland Gas Company – fire resistant / anti-static / lightweight jacket

• Programmed Marine – fire inherent / anti-static coveralls

• Wild Desert Drilling – fire resistant / anti-static coveralls, trousers and shirts

• Savanna Energy – fire resistant / anti-static coveralls

CORE COMPETENCIES

• All Rift Safety Gear garments are manufactured at certified high end safety garment factories that possess specialist knowledge and technical expertise in the field

• We maintain product quality control and product recall procedures adherent with global manufacturing standard ISO 9001:2008

• We offer our clients the option to establish an online buying portal via our company website

• We maintain strong relationships with a range of manufacturers and freight logistic companies to fulfil our clients’ needs

• We have solid financial backing of over $10M

• Rift Safety Gear comprises a highly experienced and competent management team

REASONS TO CHOOSE RIFT SAFETY GEAR

• We offer the highest quality garments for the best value

• All Rift Safety Gear garments are supplied with test reports to maintain confidence in standard of protection offered

• Your company safety apparel can be designed to any specification required

• We make quality and lead times our top priority

• We are able to hold stock for all contracted clients. We can also create order alerts to ensure that stock levels remain at an agreed percentage

• We provide unrivalled reliability and flexibility to maintain the highest standard of customer service

• Our experienced team members work hard to assist and support our client’s throughout the product development and supply process.